How to Make a Good Production File in the Garments?

Creating a Good and comprehensive Production file in the Garments Industry is crucial for ensuring the Quality and consistency of the final Product.

How to Make a Good and Comprehensive Production File in the Garments Industry? Here’s a step-by-step guide to help you prepare an effective production file:

1. Technical Specifications:

- Design Sketch: Include clear and detailed design sketches from multiple angles.

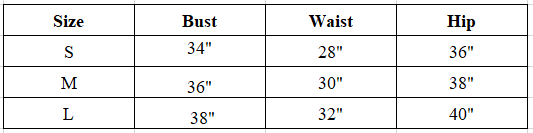

- Measurements: Provide a detailed measurement chart for all sizes.

- Fabric Details: Specify the type, composition, and weight of the fabric.

- Trims and Accessories: List all trims, buttons, zippers, labels, etc., with their specifications.

2. Bill of Materials (BOM):

- Fabric: Detailed information about the fabric, including color, width, weight, and supplier.

- Trims: Information about each trim, including type, size, color, and supplier.

- Packaging: Details on packaging materials and methods.

3. Construction Details:

- Sewing Instructions: Step-by-step sewing instructions with diagrams or photos if possible.

- Stitch Types: Specify the stitch types to be used at different stages.

- Seam Allowances: Detailed information about seam allowances for various parts of the garment.

- Finishing Details: Instructions for finishing techniques like hemming, pressing, and labeling.

4. Quality Control Specifications:

- Tolerance Levels: Define acceptable tolerances for measurements and construction.

- Inspection Points: Highlight critical inspection points in the production process.

- Testing Requirements: Details of any fabric or garment testing required (e.g., colorfastness, shrinkage).

5. Size Specification (Spec) Sheet:

- Size Chart: Comprehensive size chart with all necessary measurements.

- Grading Rules: Information on how measurements change from one size to the next.

6. Pattern and Marker:

- Pattern Pieces: Provide all pattern pieces with annotations.

- Marker Plan: Marker layout for fabric cutting to ensure efficient use of material.

7. Production Timeline:

- Schedule: Detailed production schedule with timelines for each stage of production.

- Deadlines: Specific deadlines for fabric and trim procurement, sample approval, and production start and end dates.

8. Sample Approval:

- Proto Sample: Details of the first sample made for design verification.

- Fit Sample: Sample made for fitting purposes.

- Pre-production Sample (PP Sample): Final sample before bulk production, approved for all specifications.

9. Packaging and Shipping Instructions:

- Packaging Specifications: Instructions for folding, packaging, and labeling garments.

- Shipping Instructions: Details on shipping methods, packaging materials, and documentation required for shipment.

10. Communication Log:

- Correspondence: Keep a log of all communications with suppliers and manufacturers.

- Updates: Record any changes or updates made to the production file.

Tools and Resources:

- Software: Use software like Adobe Illustrator, Corel DRAW, or specialized fashion design software for creating technical drawings and specs.

- Templates: Utilize templates for tech packs, BOMs, and size spec sheets to maintain consistency.

Example Sections of a Production File:

Design Sketch

Measurement Chart:

BOM (Bill of Materials):

How to Make a Good and Comprehensive Production File in the Garments Industry. By the Following these steps and maintaining detailed documentation, you can create a comprehensive production file that will help ensure the smooth and efficient production of your garments.

.png)

.png)