Fabric consumption calculation is one of the most crucial tasks in garment manufacturing. Accurate fabric consumption helps manufacturers manage costs, reduce wastage, and ensure smooth production processes. In this blog, we will explore the basic formula for calculating fabric consumption and its importance in garment production.

What is Fabric Consumption?

Fabric consumption refers to the amount of fabric required to produce a single garment or an entire order. It includes all the pieces of fabric needed for the body, sleeves, collars, cuffs, and other parts of the garment, as well as the allowance for seams, hems, and wastage.

Calculating fabric consumption accurately helps manufacturers:

- Control production costs

- Minimize fabric wastage

- Improve order planning and profitability

Factors Affecting Fabric Consumption

Several factors impact the amount of fabric required for garment production:

- Garment Type and Design: Different garments (e.g., shirts, pants, jackets) require varying amounts of fabric based on their construction and complexity.

- Fabric Width: The width of the fabric roll (e.g., 44 inches, 60 inches) affects how much fabric is used. Wider fabric allows more garment pieces to be cut from a single roll.

- Garment Size: Larger garment sizes require more fabric. Manufacturers often calculate fabric consumption separately for each size range.

- Pattern Layout: The way fabric pieces are arranged on the fabric (cutting layout) impacts fabric consumption. Efficient pattern layouts reduce wastage.

- Shrinkage: Some fabrics shrink after washing or ironing, so fabric consumption calculations must account for shrinkage allowances.

What is the Basic Formula for Calculating Fabric Consumption?

In the garment industry, fabric consumption is a critical factor for costing and production planning.

Accurate fabric consumption calculations help manufacturers estimate how much fabric is needed for each garment, which directly influences the total cost and profitability of production.

Whether you're producing T-shirts, dresses, or jackets, knowing the basic formula for fabric consumption is essential for efficient resource management.

In this blog, we will explore the fundamental methods and formulas used to calculate fabric consumption in garment manufacturing.

What is Fabric Consumption?

Fabric consumption refers to the amount of fabric required to produce a single garment or an entire order. It includes all the pieces of fabric needed for the body, sleeves, collars, cuffs, and other parts of the garment, as well as the allowance for seams, hems, and wastage.

Calculating fabric consumption accurately helps manufacturers:

- Control production costs

- Minimize fabric wastage

- Improve order planning and profitability

Factors Affecting Fabric Consumption

Several factors impact the amount of fabric required for garment production:

- Garment Type and Design: Different garments (e.g., shirts, pants, jackets) require varying amounts of fabric based on their construction and complexity.

- Fabric Width: The width of the fabric roll (e.g., 44 inches, 60 inches) affects how much fabric is used. Wider fabric allows more garment pieces to be cut from a single roll.

- Garment Size: Larger garment sizes require more fabric. Manufacturers often calculate fabric consumption separately for each size range.

- Pattern Layout: The way fabric pieces are arranged on the fabric (cutting layout) impacts fabric consumption. Efficient pattern layouts reduce wastage.

- Shrinkage: Some fabrics shrink after washing or ironing, so fabric consumption calculations must account for shrinkage allowances.

Basic Formula for Calculating Fabric Consumption

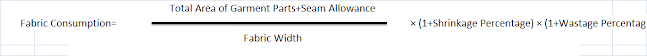

The basic formula for calculating fabric consumption is:

Where:

- Total Area of Garment Parts: Sum of the fabric area required for all garment parts (e.g., front, back, sleeves).

- Fabric Width: The width of the fabric roll in inches or centimeters.

- Number of Pieces: The total number of garment parts required for each piece of clothing.

Step-by-Step Example of Fabric Consumption Calculation

Let’s walk through a simple example for a men’s T-shirt.

Identify Garment Parts and Their Dimensions

Assume the T-shirt consists of the following parts:

- Front: 24 inches (length) x 20 inches (width)

- Back: 24 inches (length) x 20 inches (width)

- Sleeves: 9 inches (length) x 12 inches (width)

Calculate the Total Area of Garment Parts

Convert the dimensions of each part into square inches:

- Front: 24 inches x 20 inches = 480 square inches

- Back: 24 inches x 20 inches = 480 square inches

- Sleeves (two pieces): 2 x (9 inches x 12 inches) = 216 square inches

Total Area = 480 + 480 + 216 = 1,176 square inches

Consider the Fabric Width

Assume the fabric width is 60 inches.

Calculate Fabric Consumption

Now, apply the basic formula:

So, to produce one T-shirt, you will need approximately 19.6 inches of fabric length.

Additional Allowances for Fabric Consumption

When calculating fabric consumption, it’s essential to include additional allowances for the following:

- Seam Allowance: Extra fabric required for seams (usually 0.5 to 1 inch) should be added to each garment part.

- Shrinkage Allowance: Fabric often shrinks during washing, so manufacturers add a shrinkage allowance (typically 2-5%) to compensate.

- Wastage Allowance: Cutting and stitching processes often generate waste, so manufacturers add a wastage percentage (usually 2-3%) to the total fabric consumption.

Modified Fabric Consumption Formula

Taking these allowances into account, the modified formula becomes:

For instance, if the shrinkage percentage is 3% and the wastage percentage is 2%, the formula for our T-shirt example would be:

So, the final fabric consumption for one T-shirt, considering allowances, is approximately 20.6 inches.

Conclusion

Understanding and accurately calculating fabric consumption is crucial in garment manufacturing. The basic formula for fabric consumption takes into account the garment parts, fabric width, and number of pieces.

By factoring in seam, shrinkage, and wastage allowances, manufacturers can ensure they order the correct amount of fabric, minimizing costs and wastage.

.png)

.png)